introduction

Pulse damper is a vital piece of equipment in fluid conveying systems that helps reduce the fluctuations and vibrations caused by fluid flow in pipelines. Using high-quality materials in the construction of this equipment is of particular importance. One of the best materials for making a pulsation damper is stainless steel. In this article, we have checked the features, benefits and applications of stainless steel pulsation damper.

What is a pulse suppressor?

Definition and function

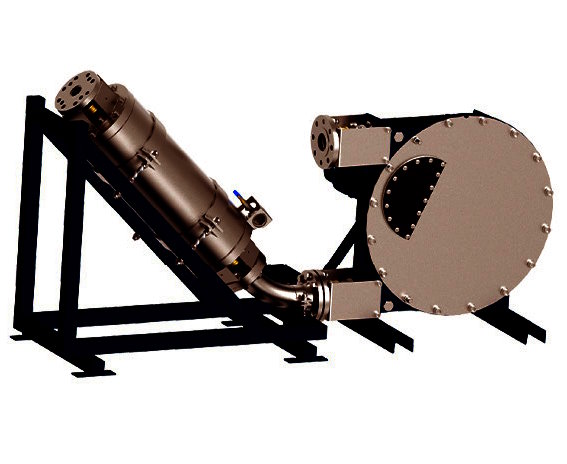

A pulsation damper is a mechanical device used to reduce pressure and flow fluctuations in pipelines and fluid transportation systems. This device typically consists of a gas or liquid-filled chamber that absorbs the fluctuations and stabilizes the flow. A pulsation damper helps improve the performance of pumping and fluid transportation systems and prevents equipment damage.

Main Ingredients

- Chamber : The part in which a liquid or gas is stored.

- Diaphragm : The part that helps divide the chamber into two parts and absorbs fluctuations.

- Fittings : The parts that connect the pulse damper to the piping system.

What is stainless steel?

Definition and Features

Stainless steel is a steel alloy containing at least 10.5% chromium. This material is widely used in various industries due to its high resistance to corrosion, rust and staining. Stainless steel is available in different types such as austenitic, ferritic, martensitic and duplex.

Main features of stainless steel

- High corrosion resistance : Stainless steel is resistant to corrosion and rust.

- High temperature resistance : Stainless steel can perform well at high and low temperatures and maintain its mechanical properties.

- Dimensional stability : Stainless steel has high dimensional stability and good resistance to temperature and pressure changes.

- High Durability and Long Life : Stainless steel has high durability and long life.

- Beautiful and shiny appearance : Stainless steel has a beautiful and shiny appearance that gives the equipment an attractive look.

Advantages of using stainless steel pulse damper

Reduce oscillations and vibrations

The use of stainless steel pulsation damper helps reduce pressure and flow fluctuations in pipelines and fluid transportation systems. This device helps absorb and reduce fluctuations caused by pumps and fluid transportation equipment and helps improve system performance.

Extend equipment life

The stainless steel pulsation damper helps prevent equipment damage caused by pressure and flow fluctuations. This device helps increase the productive life of pumps, pipes and other equipment and reduces the need for frequent repairs and maintenance.

Chemical and corrosion resistance

One of the main advantages of using stainless steel in the manufacture of a pulse damper is its high resistance to chemicals and corrosion. This feature allows the pulse damper to perform well in corrosive environments and with various chemicals.

Performance at high and low temperatures

The stainless steel pulse damper can work well in high and low temperature and maintain its mechanical properties. This feature helps this device to be used in different environmental conditions.

Beautiful and shiny appearance

The stainless steel gives the pulse damper an attractive appearance due to its beautiful and shiny finish. This feature helps the equipment to have a professional and elegant appearance in industrial and laboratory environments.

Easy to maintain and clean

The stainless steel pulse humidifier is easy to maintain and clean. The resistance to chemicals and corrosion allows this device to be cleaned without the need for harsh chemicals.

Stainless Steel Pulse Damper Applications

Chemical industry

In the chemical industry, stainless steel pulse damper is used to reduce pressure and flow fluctuations in pipelines and chemical conveying systems. The high chemical resistance and precision of this device help improve the efficiency and quality of chemical processes.

Pharmaceutical industry

In the pharmaceutical industry, stainless steel pulsation damper is used to reduce pressure and flow fluctuations in drug and solution conveying lines. High precision and chemical resistance help improve the quality and safety of pharmaceutical products.

Food and Beverage Industry

In the food and beverage industry, stainless steel pulsation dampers are used to reduce pressure and flow fluctuations in food and beverage conveying lines. Chemical resistance and beautiful appearance help improve the efficiency and quality of food products.

Oil and Gas Industries

In the oil and gas industries, stainless steel pulsation damper is used to reduce pressure and flow fluctuations in oil and gas transmission lines. Corrosion and chemical resistance helps improve the efficiency of oil and gas operations.

Water and Wastewater Industries

In the water and wastewater industries, stainless steel pulsation damper is used to reduce pressure and flow fluctuations in water and wastewater transmission lines. Chemical and corrosion resistance helps improve the efficiency of treatment processes and reduce environmental pollution.

Paint and coating industry

In the paint and coating industries, stainless steel pulsation damper is used to reduce pressure and flow fluctuations in paint and coating solution conveying lines. High precision and chemical resistance help improve product quality and uniformity.

Important points in the maintenance and use of stainless steel pulse damper

Regular cleaning

Regular cleaning of the stainless steel pulse damper helps improve its performance and durability. This process involves cleaning the components of debris and deposits.

Periodic inspections

Periodic inspections of the pulse damper help identify potential problems and defects . These inspections include checking the physical condition of the components and the operation of the device.

Use of appropriate chemicals

Using the right chemicals to clean and maintain your stainless steel pulse humidifier will help maintain its quality and efficiency. Harsh chemicals that may damage stainless steel materials should be avoided.

Proper storage

Proper storage of stainless steel pulse damper will increase the useful life and reduce the risk of physical damage. These devices should be stored in dry, cool places away from direct sunlight.

conclusion

Due to its exceptional features such as high chemical resistance, corrosion resistance, high precision and long life, stainless steel pulse damper is used in many industries including chemical, pharmaceutical, food and beverage, oil and gas, water and wastewater, paint and coating. It is widely used. These devices help improve the efficiency, quality and safety of processes and products. By properly maintaining and using stainless steel pulse damper, you can benefit from the productive life and optimum performance of this equipment and avoid problems caused by pressure and flow fluctuations.